We are thrilled to announce the launch of our latest product, the rbs Injection Resin LV Kit.

The rbs Injection Resin LV Kit, a new addition to our rbs product range is a two-component, low viscosity, fast curing epoxy sealing system specially formulated for repairs to cracks in concrete and solid masonry. It offers an efficient, and long-lasting solution for repairing cracks, ensuring that structures remain safe and robust.

Cracks in concrete and masonry can occur due to many different reasons including, but not limited to, shrinkage, overloading, environmental factors and corrosion. These cracks can weaken the overall structure of buildings and over time they can widen, compromising the load bearing capacity and potentially leading to structural failure. These cracks can also allow water to penetrate which can lead to moisture related issues.

The rbs Injection Resin LV Kit is the ideal solution for this and includes all of the components necessary for successful concrete and solid masonry crack repairs on walls and floors. This kit incorporates not only the crack sealer and injection resin (supplied in cartridges that will fit standard sealant guns) but also mixer nozzles, ports, extension tubes, connectors and ancillaries.

At Resapol, we are committed to delivering quality products that meet the needs of our customers. The rbs Injection Resin LV Kit is no exception, representing a reliable solution for crack repairs that you can count on. This exciting new addition to our rbs product range reaffirms our commitment to providing the construction industry with high-quality materials and solutions.

The rbs Injection Resin LV Kit is in stock and available for purchase through our network of distribution depots. For more information on this product or to place an order, visit our official product page or contact your local depot’s technical sales teams for assistance.

Areas of Use

- Low pressure injection of cracks in concrete and solid masonry

- Gravity feed of cracks in horizontal concrete and

horizontal masonry - Fast repairs to concrete and masonry cracks

- Suitable for walls and floors

Product Benefits

- Low viscosity, rapid curing crack sealer and epoxy-based injection resin

- As strong as concrete when cured

- Low viscosity, 100% solids epoxy

- No drilling required, no need to excavate

- Cartridges that fit into standard sealant guns

- Comes with convenient mixer nozzles for both the crack sealer and injection resin

- Perforated box to hold injection ports

What Each Kit Contains

Each box contains the complete kit that comprises of:

| Item | Quantity Per Kit |

|---|---|

| 250ml Injection Resin | 3 |

| Mixer Nozzles | 2 |

| Applicator Fan | 2 |

| 300ml Crack Sealer | 2 |

| Cartridge Outlet Plug | 3 |

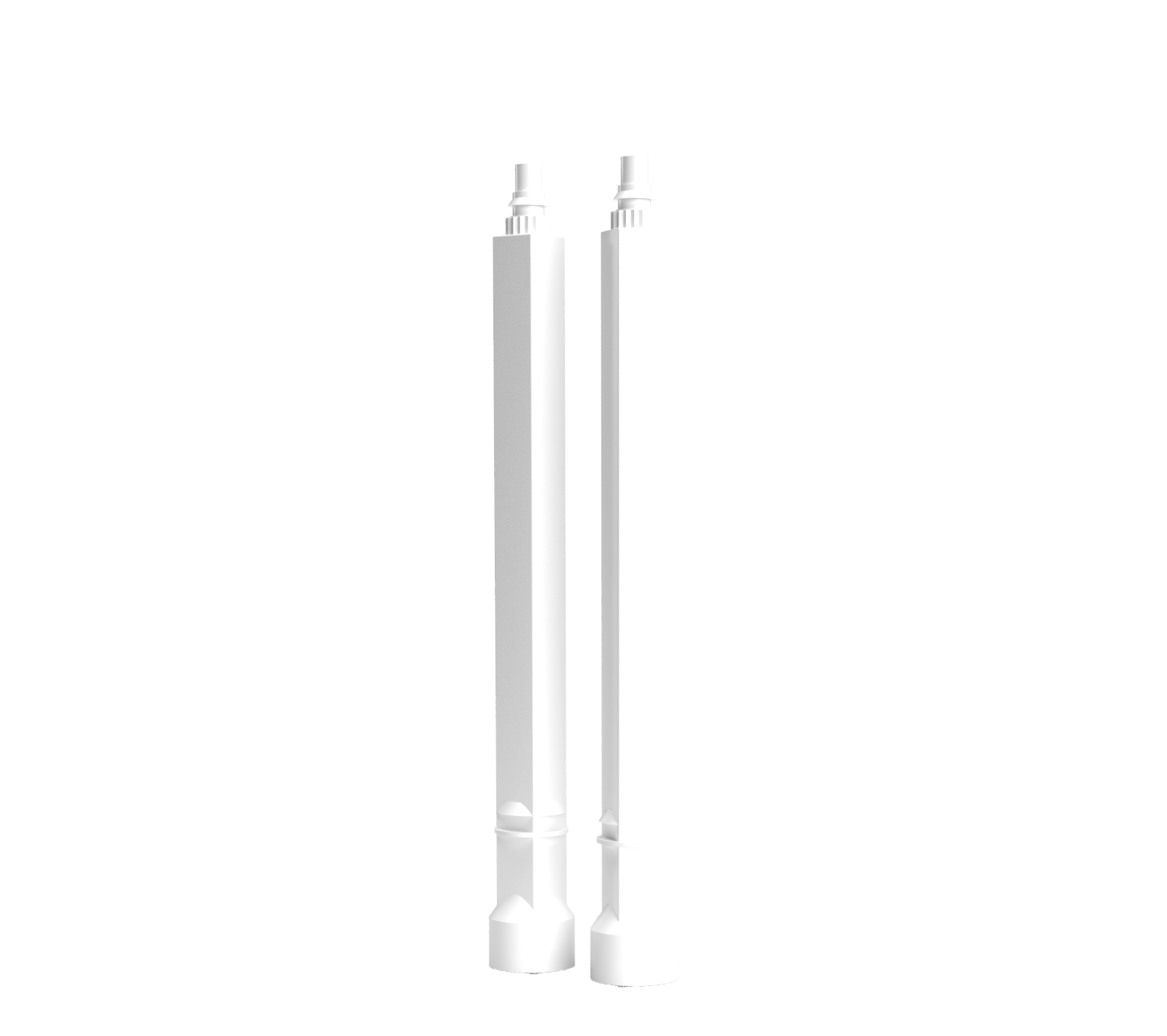

| Injection Resin Mixers with Extension Tube | 3 |

| Push Fit Connector | 1 |

| Injection Ports | 16 |

| Pairs of Gloves | 2 |

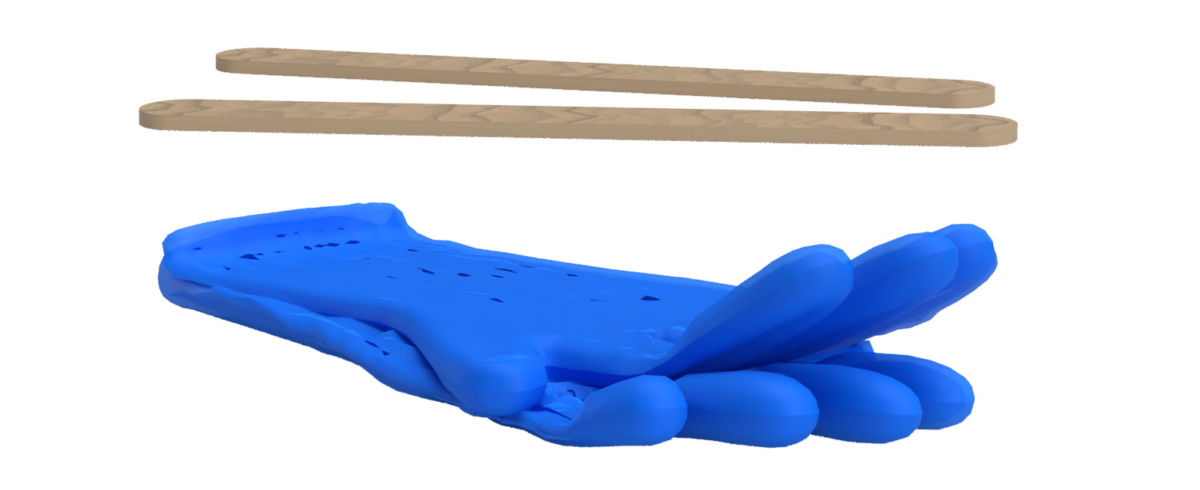

| Wooden Applicators | 2 |

250ml Injection Resin

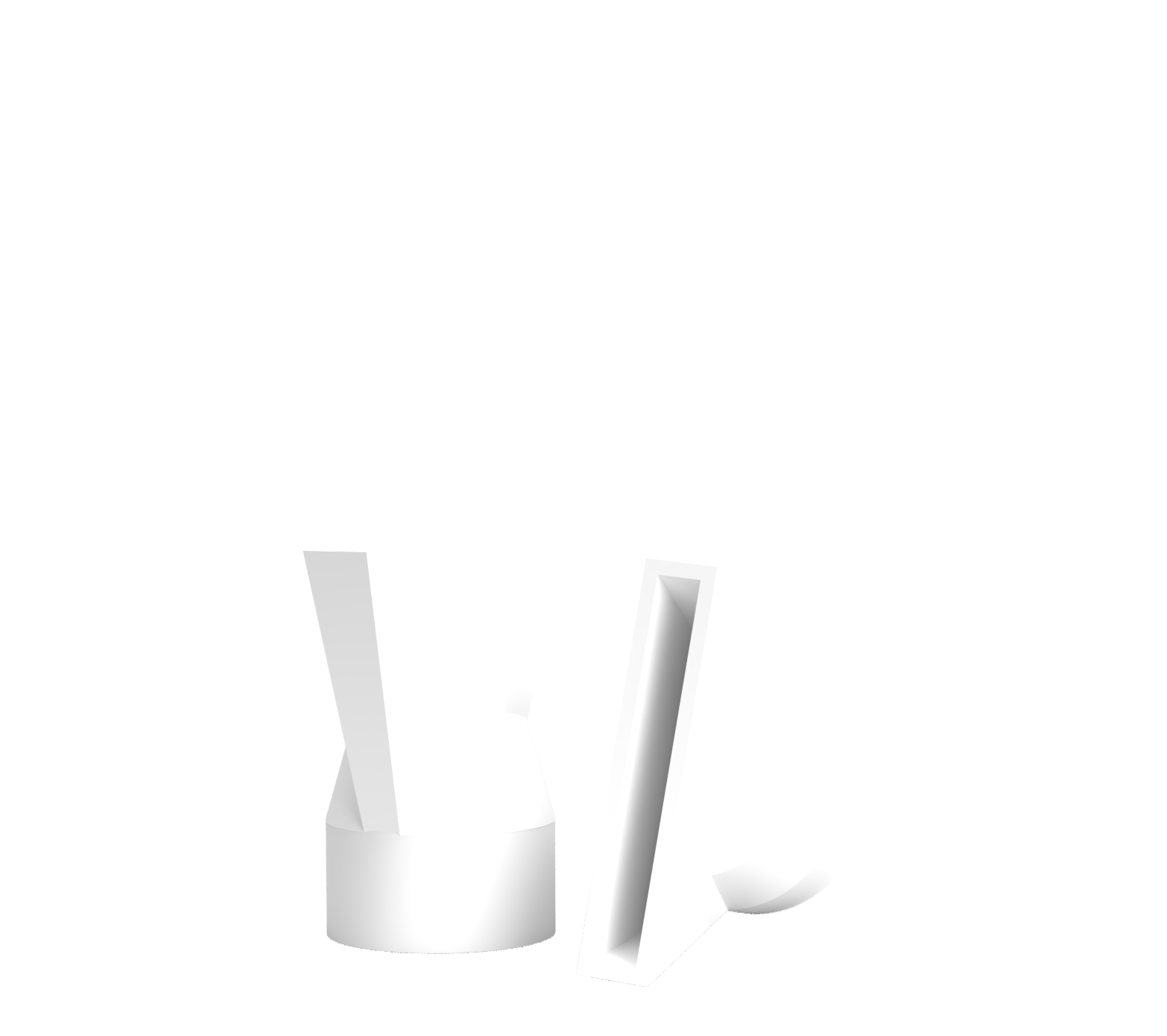

300ml Crack Sealer

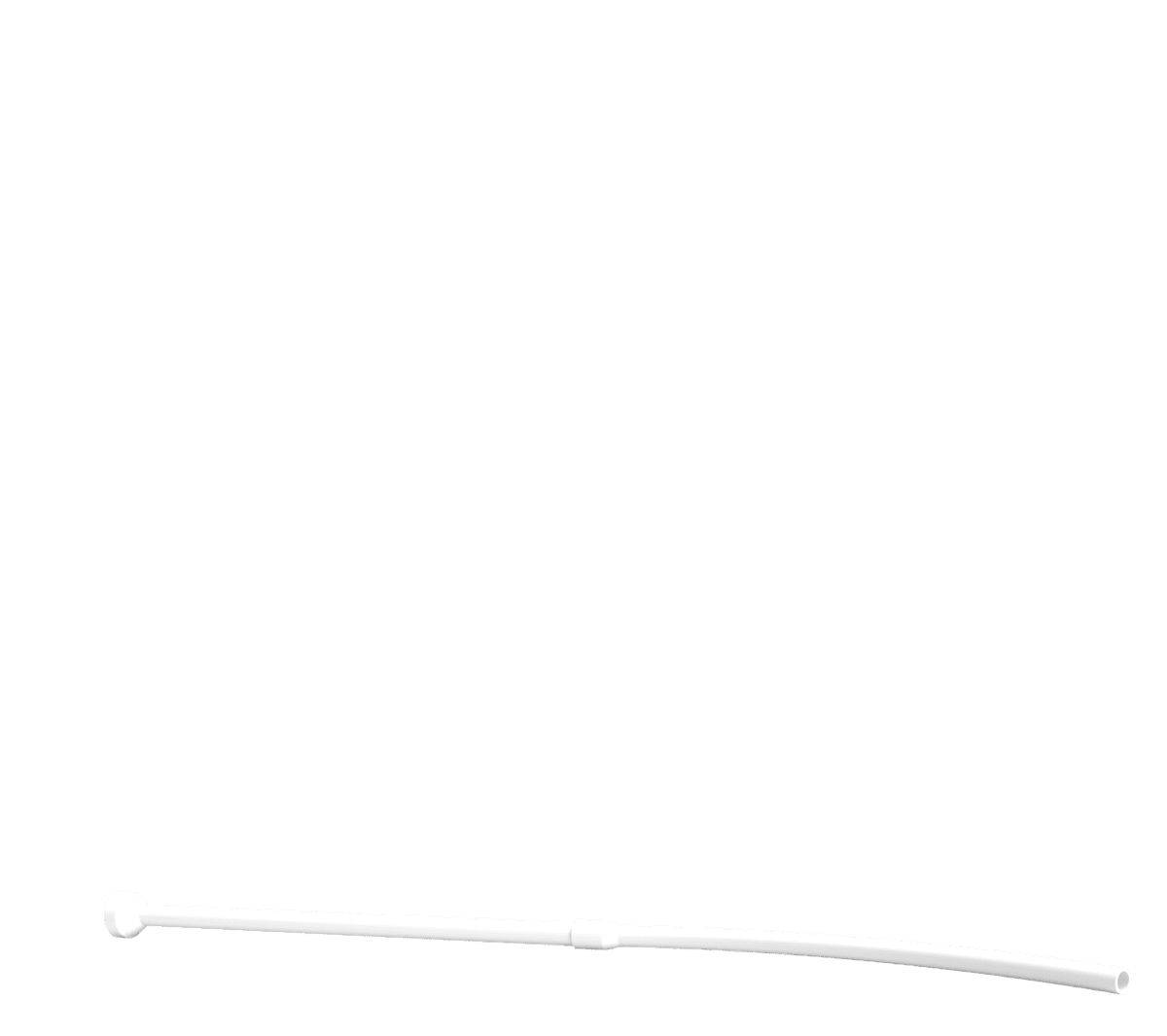

Push Fit Connector

Mixer Nozzles

Cartridge Outlet Plug

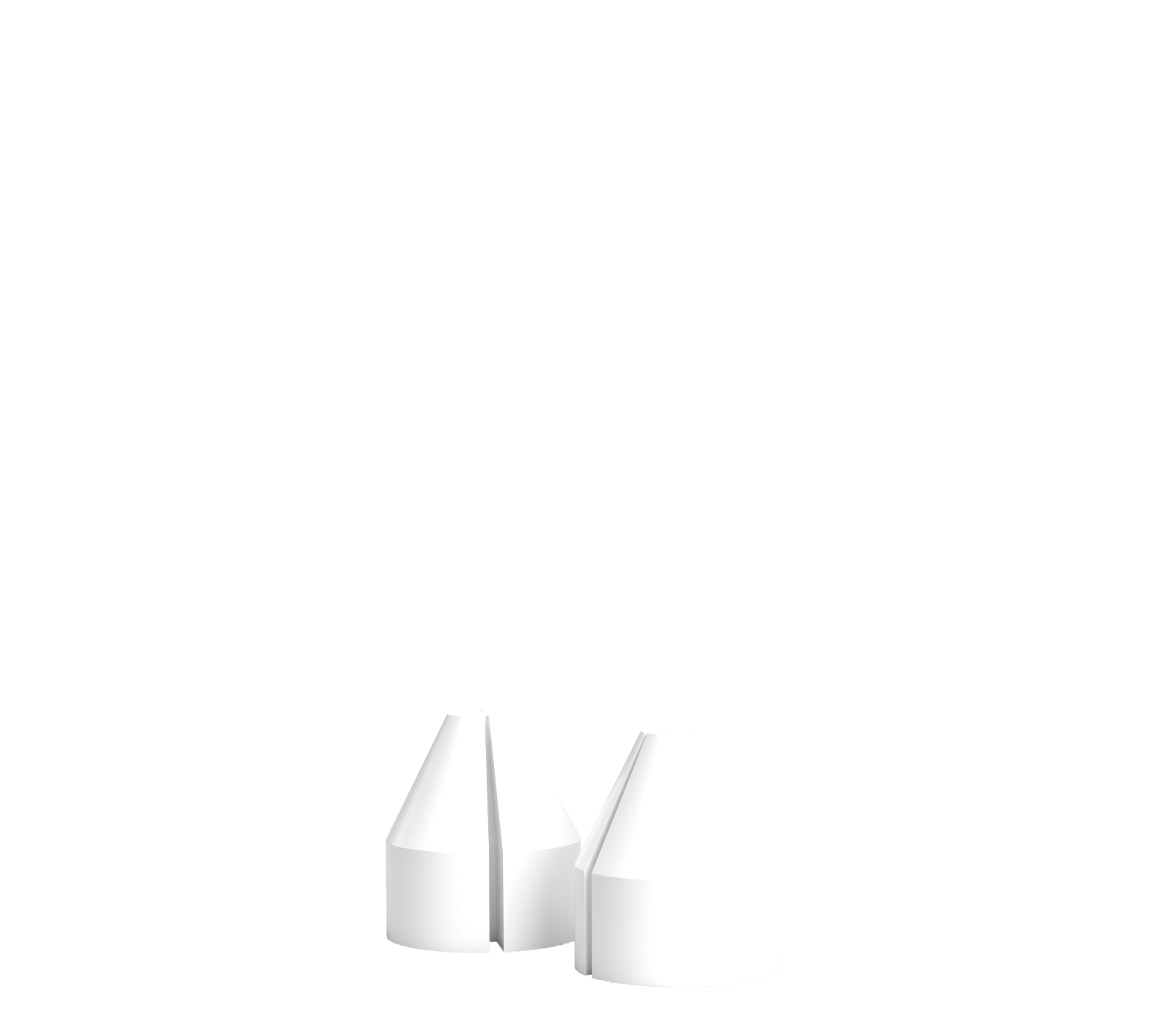

Injection Ports

Applicator Fan

Injection Resin Mixers

with Extension Tube

Gloves & Wooden Applicators

Step by Step Guide

- Fit injection ports to the crack, spacing evenly using the rbs Crack Sealer.

- Seal the crack and around each of the injection ports with the rbs Crack Sealer.

- Allow to cure.

- Fit the rbs Injection Resin to the ports using the injection tube.

- Start the injection at the lowest port, repeating on the next port up when the resin reaches it, until the crack is completely full.

- Allow to cure.

- Use appropriate tools to fully remove all injection ports and rbs Crack Sealer.

- Make any final repairs to the surface of the concrete.

Application Advice

Paul Rigby | National Technical Support Manager

- Always wear eye protection and disposable gloves. This is a must!

- Assuming a crack is 1mm wide and 100mm deep a 1 litre of resin will fill a crack approximately 10m long. The choice of the type of injection resin will be dependent on the width of crack. Also it is important to ensure cracks are dormant.

- Always gently pump the resin through the mixer nozzle and hose ensuring not to exert too much pressure.

If you feel resistance, stop pumping immediately. Otherwise excessive pressure may break the seal over the crack. Wait approximately 30 seconds and then reapply pressure; repeat this procedure 3 times. The resin should begin to exude from the next adjacent injection port fairly quickly. If it does not, move to the next port and pump resin until flowing resin is detected on the previous port. Then seal off the port and continue injection process.

- Always start at the bottom of the crack so air is displaced upwards as work proceeds.

- Allow 24 hours for curing of the injection resin. Then the sealed injection ports may be broken off. Any depression or making good can then be carried out. To achieve a smooth finish to the surface, remove any crack sealer excess using a grinding wheel.

- Clean tools with a solvent based cleaner before the resin cures.